Chinese (Simplified)

Turkish

Swedish

Slovak

Romanian

Polish

Dutch

Italian

Hungarian

French

Finnish

Spanish

English

German

Danish

Czech

Hot Isostatic Pressing (HIP) Services Improves component integrity and strength by application of extreme pressure and heat.

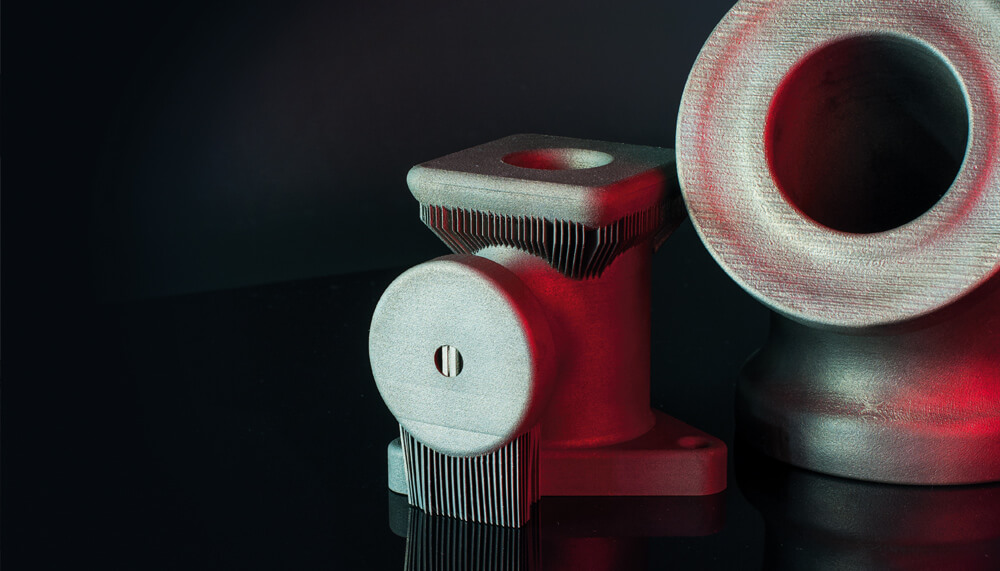

HIP PF inc. Powdermet® Additive manufacturing of often complex components by combining with HIP.

Specialty Stainless Steel (S³P) Processes Improves the strength, hardness and wear resistance of stainless steel. Standard heat treatments negatively impact the corrosion resistance of stainless steel, but our proprietary S³P processes can provide dramatically improved material properties while maintaining corrosion resistance.

Surface Technology Enhances component life using ceramic and metal coatings.

Low Pressure Carburising (LPC) Obtains a hardened surface and a tough core under vacuum using a cleaner process than atmospheric carburising, providing improved wear resistance and fatigue life with less distortion.

Corr-I-Dur® (CiD) Improves corrosion resistance and wear properties and is primarily used as a sustainable substitute for hard chrome.

Product life is extended by accurately treating products, carried out in precisely controlled industrial furnaces that can heat to temperatures above 1000°C and use quenchants like oil, water or nitrogen gas to cool the heated material. During the process, the microstructure of the metal transforms, resulting in the hardening or softening of the material depending on the

process. Engineers can design thinner, lighter, but stronger components with the help of Classical Heat Treatment. The extended life of our customers’ products positively impacts the environment by reducing their carbon footprint.

We provide an indispensable set of processes within the manufacturing chain of most of the products used in daily life. By providing wear resistance, strength or toughness, depending on the application, the components we treat last longer, reduce downtime, increase the lifespan of the products our customers manufacture and improve the sustainability of their products. Surface hardness can be controlled by diffusing elements such as carbon and nitrogen into the metal during the heating stages of the process. The heat treatment of products impacts daily life, whether it’s a vehicle seatbelt buckle to ensure that it keeps the passenger safe during an accident or a turbine blade bringing power to your neighbourhood.

© 2024 Bodycote