loading

Safety Critical Service - a component journey

Aeropsace Engine Shaft

The main drive shaft in a civil aircraft engine is a safety critical component. In service part failure could mean disaster. Thermal processing is essential to ensure this part has the necessary material properties to operate effectively, keeping the aircraft in the air.

The component begins life as steel bar from which a forging is made.

The forged shaft is hardened and tempered to give the correct tensile strength.

Rough machining is carried out, usually to within 1/16th inch of the final part size.

The shaft is stabilised at approximately 50°C below the final tempering temperature to remove any machining stresses.

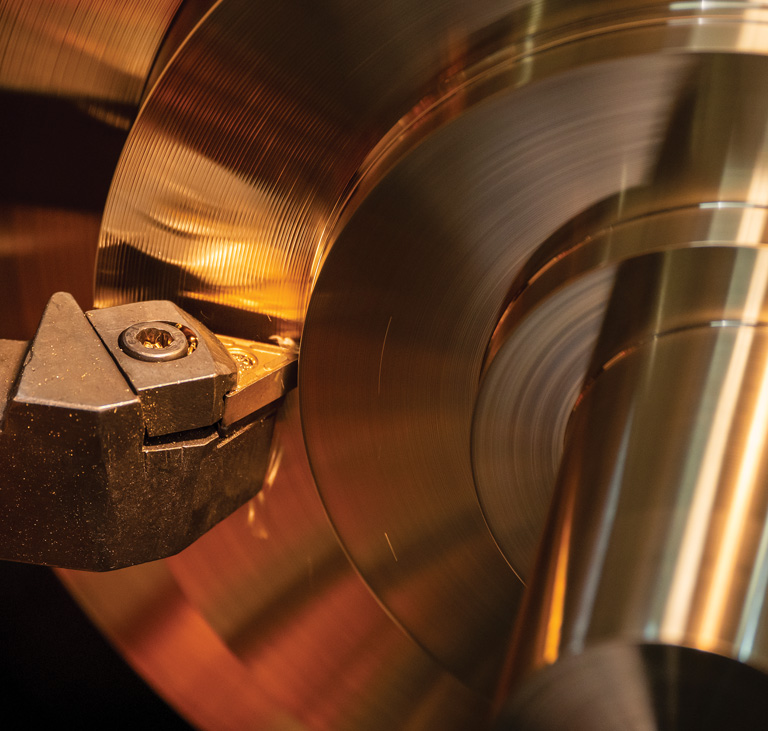

The part undergoes final machining and grinding.

Areas that do not require surface hardening are masked using bronze, tin or copper plating and the shaft is then gas nitrided at a temperature not exceeding the stabilising temperature. This diffuses nitrogen into the surface to provide high hardness and excellent wear resistance.

Post-nitriding, the plating and the white layer (nitrogen-rich layer which does not diffuse into the surface) are removed.

End application – aircraft, or land-based gas turbine, engine.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote

Denotes the parts of the component journey undertaken by Bodycote