loading

Powder Power - a component journey

VALVE BODY

Valve components operating in the harsh environments of the oil & gas and chemical industries must withstand extreme material demands and resist attack from a variety of aggressive environments.

Bodycote Powdermet® technologies* are a group of processes used in the production of complex components. These processes utilise near net shape (NNS), selective surface net shape (SSNS) and 3D printing techniques either in combination or on their own to produce cost effective components with minimal production time. Powdermet® technologies produce fully consolidated components that cannot be manufactured to the same degree of complexity or material integrity by forging or casting processes.

*Patents pending

The valve body begins life as high quality gas atomised stainless steel and nickel-based powders.

Following material selection, Bodycote’s design engineers will work closely with customers to explore the unique and flexible component design opportunities afforded by Bodycote Powdermet® technologies. When the final NNS component design is received from the customer, Bodycote will create an engineering drawing.

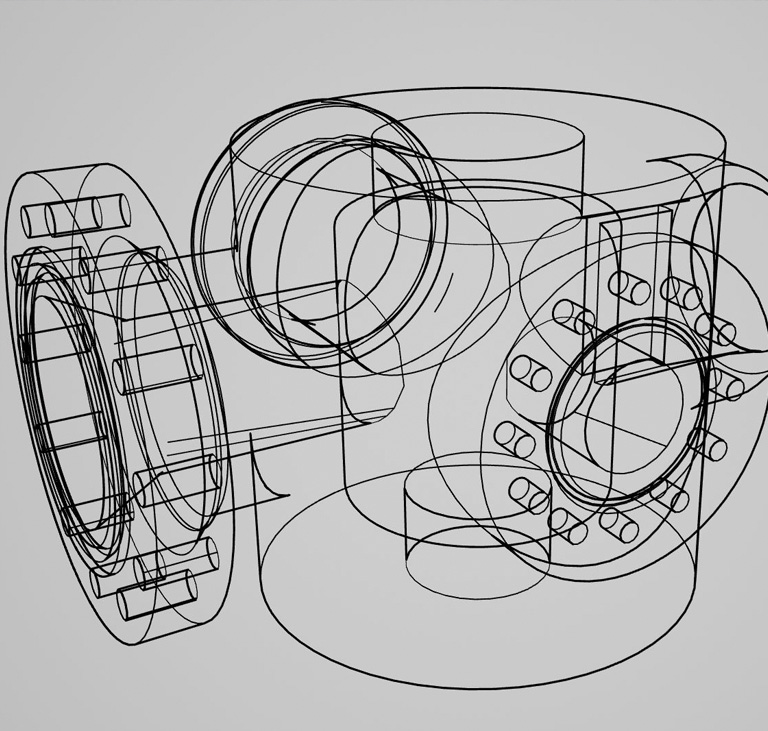

Component design is then translated into a pre-HIP capsule design where skilled engineers generate the capsule by using a combination of advanced methods which can incorporate 3D printing to produce the complex capsule assembly.

The fabricated capsule, almost identical in shape to the finished component but larger in size, is filled with powder.

The encapsulated PM valve is then HIPed using high temperatures and pressures which allows the powder to become 100% dense and form an NNS component.

After HIP the NNS component is solution heat treated and water quenched to achieve optimum material properties which are isotropic in nature.

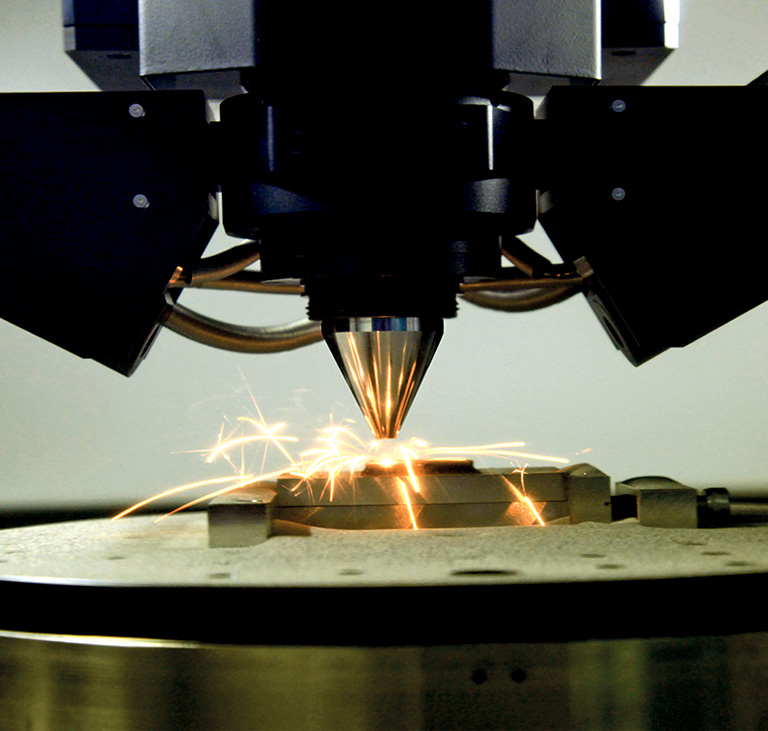

The HIPed and heat treated NNS shape valve body is laser scanned to compare the dimensions of the actual component with the NNS product drawing.

Finally the component can be pickled or machined to remove the capsule material resulting in a PM HIP NNS valve body which is inspected using ultrasonic testing techniques.

End application – Offshore oil, chemical or energy industries.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote

Denotes the parts of the component journey undertaken by Bodycote