loading

Catching the waves - a component journey

Wave energy converter

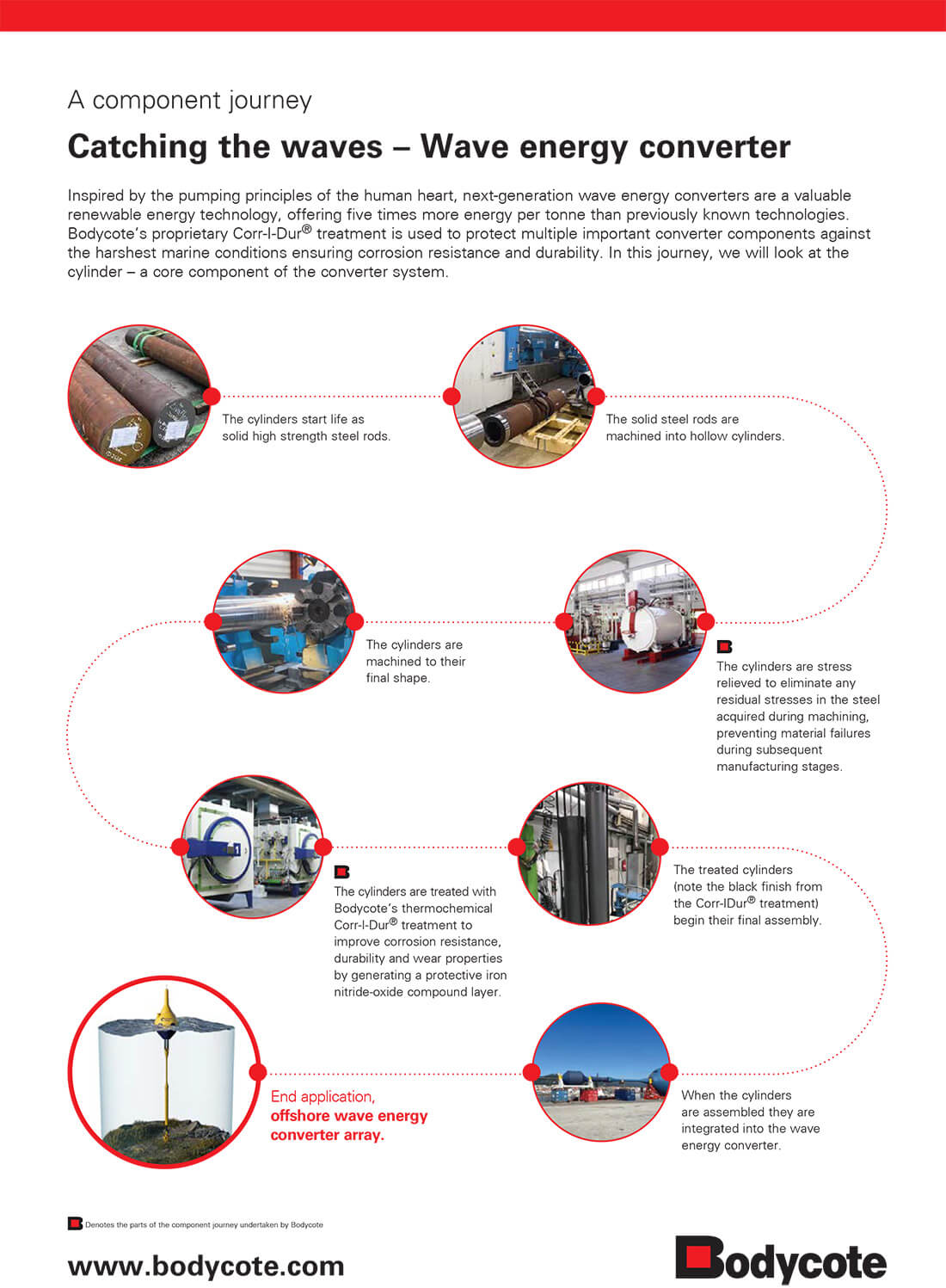

Inspired by the pumping principles of the human heart, next-generation wave energy converters are a valuable renewable energy technology, offering five times more energy per tonne than previously known technologies. Bodycote’s proprietary Corr-I-Dur® treatment is used to protect multiple important converter components against the harshest marine conditions ensuring corrosion resistance and durability. In this journey, we will look at thecylinder – a core component of the converter system.

The cylinders start life as solid high strength steel rods.

The solid steel rods are machined into hollow cylinders

The cylinders are stress relieved to eliminate any residual stresses in the steel acquired during machining, preventing material failures during subsequent manufacturing stages.

The cylinders are machined to their final shape.

The cylinders are treated with Bodycote’s thermochemical Corr-I-Dur® treatment to improve corrosion resistance, durability and wear properties by generating a protective iron nitride-oxide compound layer.

The treated cylinders (note the black finish from the Corr-IDur® treatment) begin their final assembly.

When the cylinders are assembled they are integrated into the wave energy converter.

End application – offshore wave energy converter array.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote

Denotes the parts of the component journey undertaken by Bodycote