loading

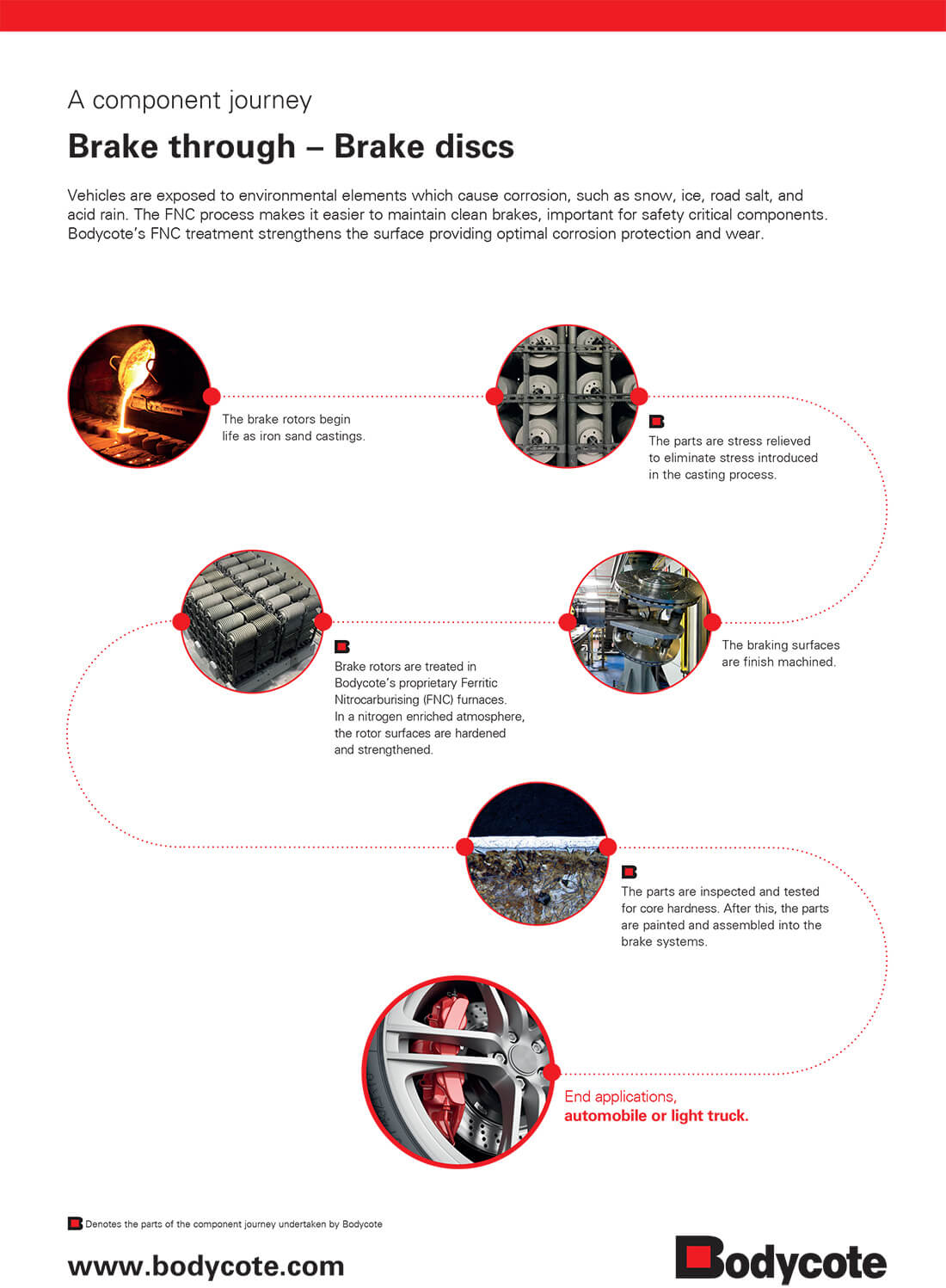

Brake through - a component journey

Brake Discs

Vehicles are exposed to environmental elements which cause corrosion, such as snow, ice, road salt, and acid rain. The Ferritic Nitrocarburising (FNC) process makes it easier to maintain clean brakes, important for safety critical components. Bodycote's FNC treatment strengthens the surface providing optimal corrosion protection and wear.

The brake rotors begin life as iron sand castings.

The parts are stress relieved to eliminate stress introduced in the casting process.

The braking surfaces are finish machined.

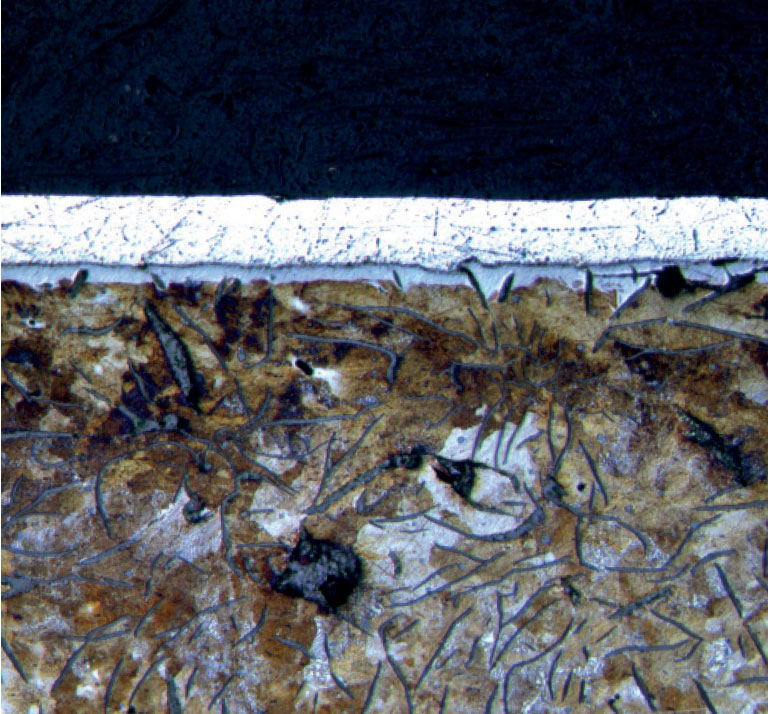

Brake rotors are treated in Bodycote's proprietary FNC furnaces. In a nitrogen enriched atmosphere, the rotor surfaces are hardened and strengthened.

The parts are inspected and tested for core hardness. After this, the parts are painted and assembled into the brake systems.

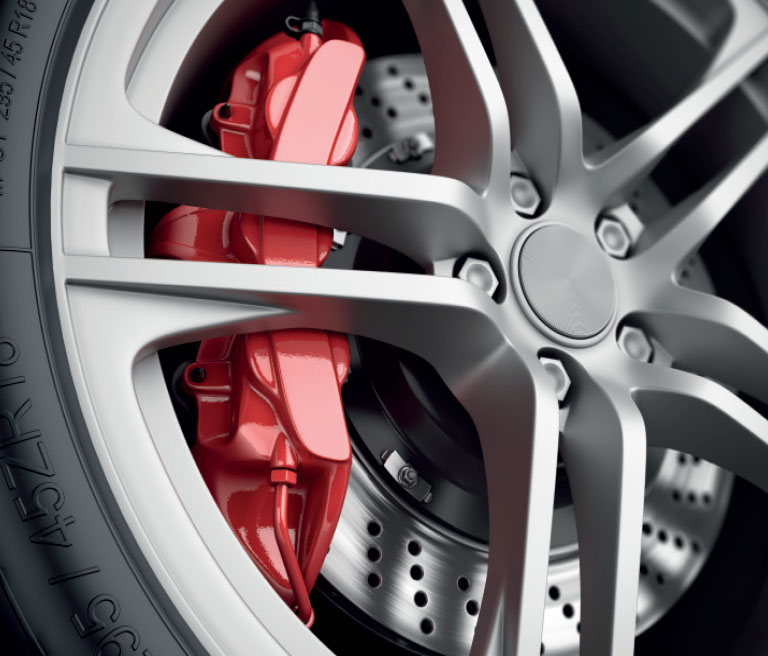

End application - Automobile or light truck.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote

Denotes the parts of the component journey undertaken by Bodycote