Hot Isostatic Pressing

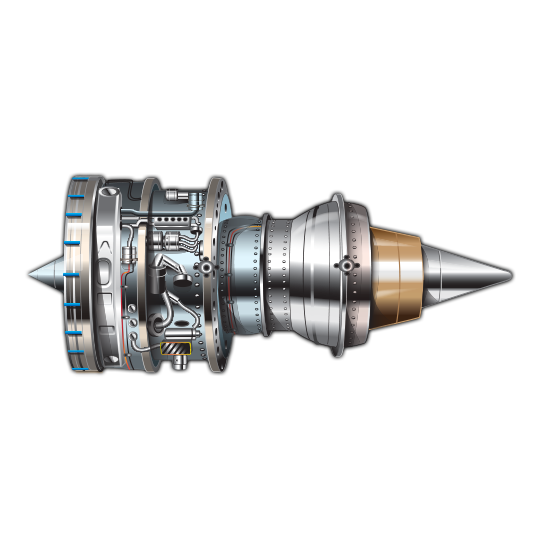

The demanding environment in aerospace applications, especially jet engines, has long required the use of Hot Isostatic pressing (HIP) to ensure consistent, defect-free material characteristics to ensure long term high integrity operations.

Working together with customers, Bodycote can provide cost-effective development of exotic and novel materials using HIP technology. New classes of raw materials, such as metal matrix composites (MMCs), were developed using the HIP process. For example, an aluminium alloy matrix with a high proportion of silicon carbide ceramic particles may be compacted to full density by the HIP process to give a very light and stiff material. Many precision airframe castings from alloys such as titanium, aluminium and steel are HIPed to ensure integrity, optimise mechanical properties and improve fatigue life.

Find out more about Bodycote Hot Isostatic Pressing.

Key solutions:

- Densal® - aluminium densification

- Densification of superalloy and titanium castings

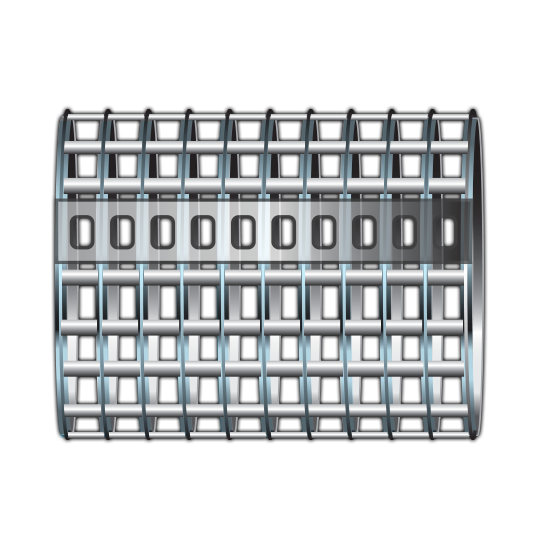

- Powdermet® manufacture of complex net and NNS powder metallurgy components and novel materials

- Diffusion bonding of complex geometries

- HIP brazing

- HIP cladding

Our aerospace solutions include: Hot Isostatic Pressing, Surface Technology and Heat Treatment.