Kolsterising®

What is Kolsterising®?

Hardened, corrosion resistant stainless steel? No problem.

Kolsterising® is an industry-proven, surface hardening technology for grades of stainless steel, cobalt and nickel-based alloys, providing ultimate hardness and improved mechanical and wear properties with no loss of corrosion resistance.

Offered exclusively by Bodycote, Kolsterising® is part of Bodycote’s Specialty Stainless Steel Processes (S³P) family, a group of technologies designed specifically to provide value-adding metallurgical treatment tailored to the unique challenges of stainless steel.

Kolsterising® and other Bodycote S³P treatments have been successfully implemented for over 20 years in a wide variety of industries. Many technical publications have reported impressive results that demonstrate considerable improvements in the mechanical properties of steel surfaces treated by S³P.

Galling… gone

Stainless steel alloys are commonly used in corrosive environments for their superb corrosion resistance. Unfortunately these alloys exhibit poor galling and wear resistance limiting their life or range of application. This is why many industrial applications rely on Kolsterising® to eliminate galling. Kolsterising® not only overcomes the galling phenomenon, but also dramatically improves wear resistance and fatigue strength.

In the untreated condition a threshold galling stress of 45.5 MPa (6.6 KSI) was measured. Following Kolsterising® treatment, galling was completely eliminated. At a load setting of 842.5 MPa (122.2 KSI) the compressive yield strength of the material was exceeded, yet no galling was observed.

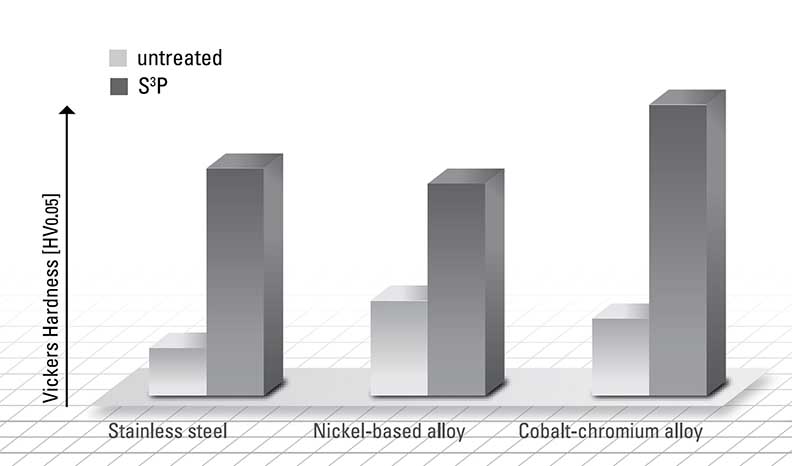

Working harder

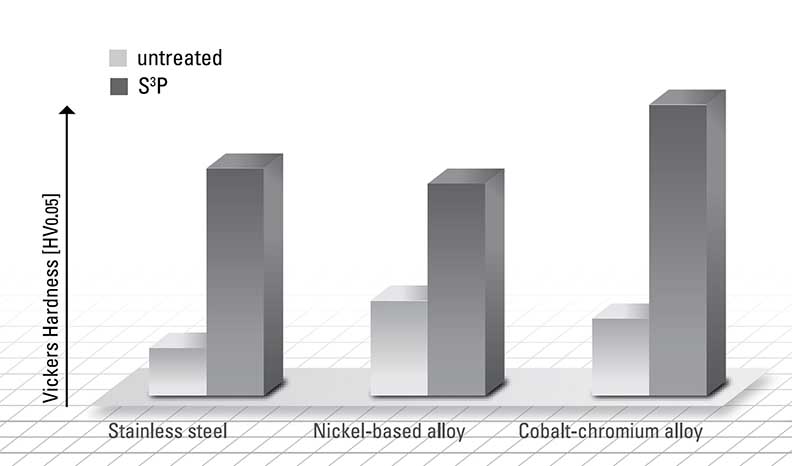

A comparison of surface hardness before and after Bodycote’s Kolsterising® (S3P) treatment. S3P treated materials show higher levels of hardness, resulting in improved wear resistance.