Hot Isostatic Pressing Densal®®

Why Densal®?

Aluminium casting offers the opportunity to produce cost-effective complicated net-shape components regardless of casting technique or the alloy composition used. Gas and shrinkage-porosity can exist in the castings, negatively influencing the mechanical properties of the component.

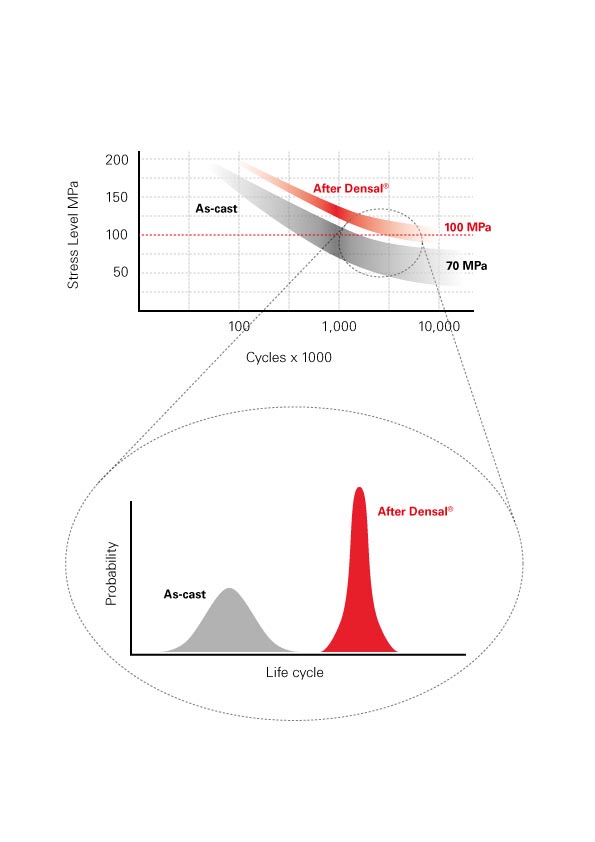

By removing this porosity, Densal® improves the performance of aluminium castings which are subjected to high dynamic loads, such as are seen in performance-critical applications.

What does Densal® deliver?

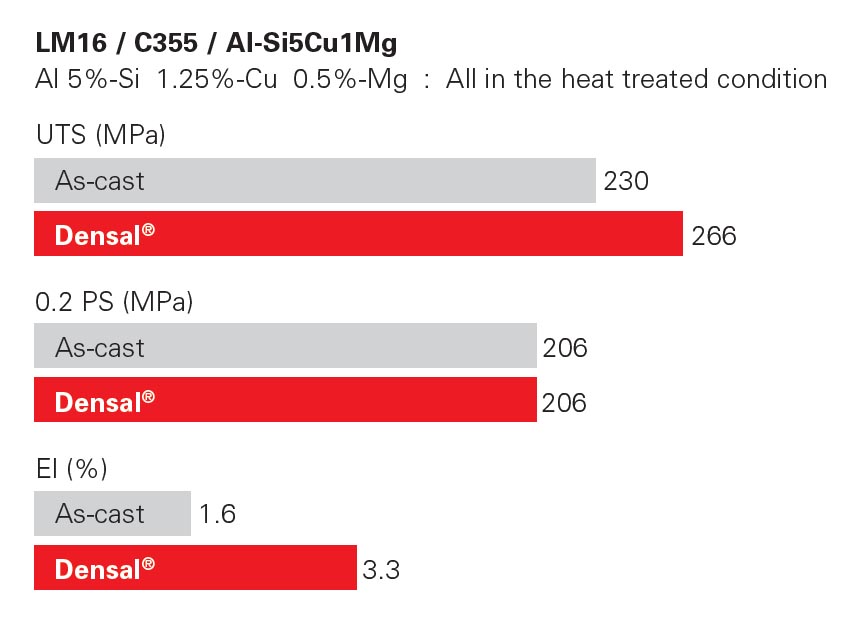

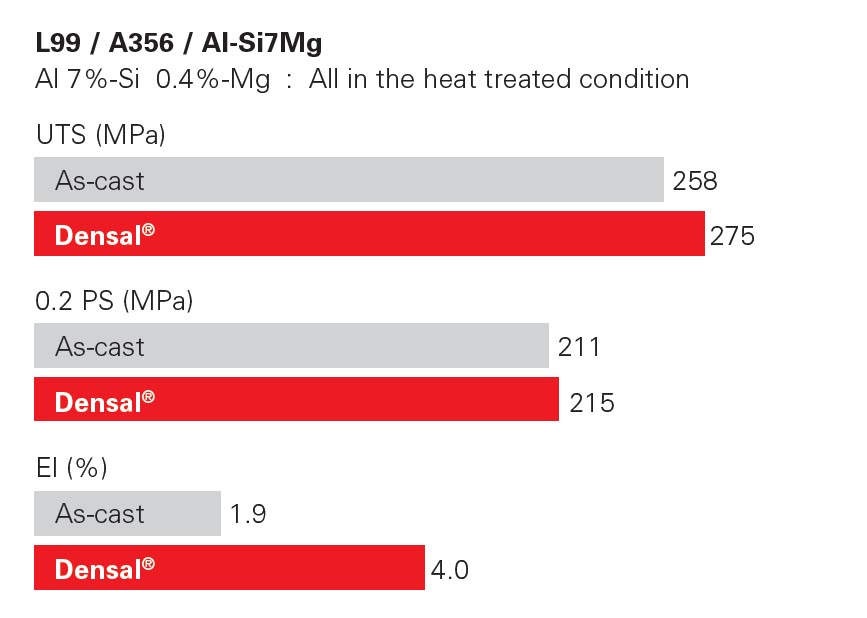

- Increased mechanical strength

- Longer fatigue life

- Uniform mechanical properties

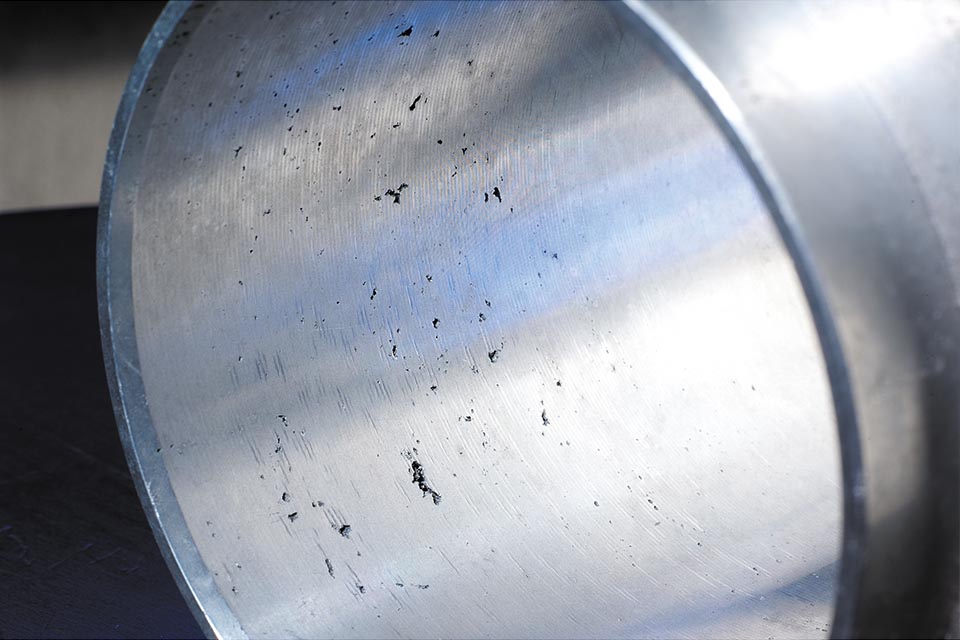

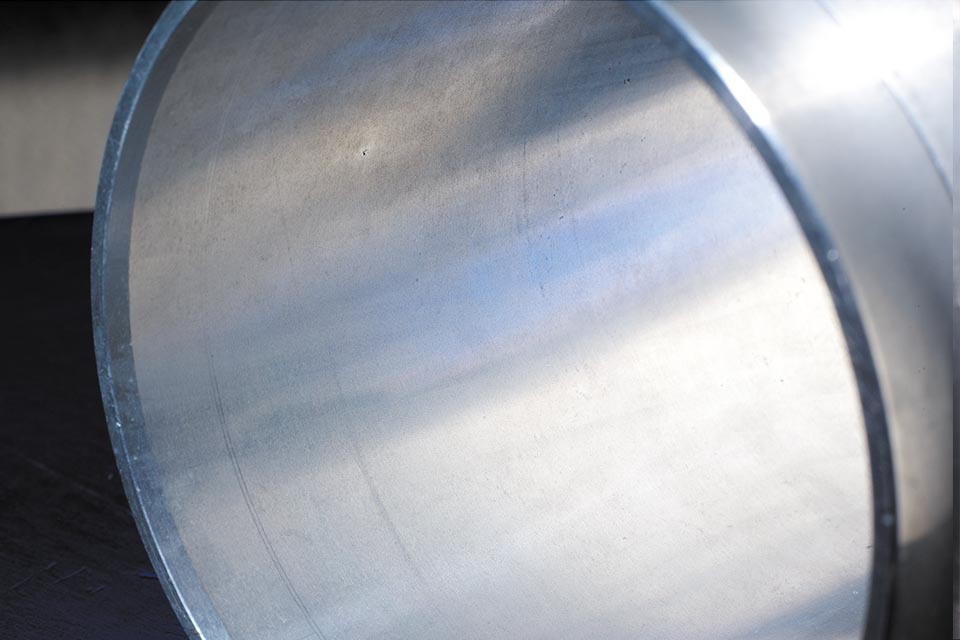

- Pore-free machined surfaces

- Reduced property scatter

- Improved x-ray inspection acceptance

- Enhanced surface finish

When to use Densal®?

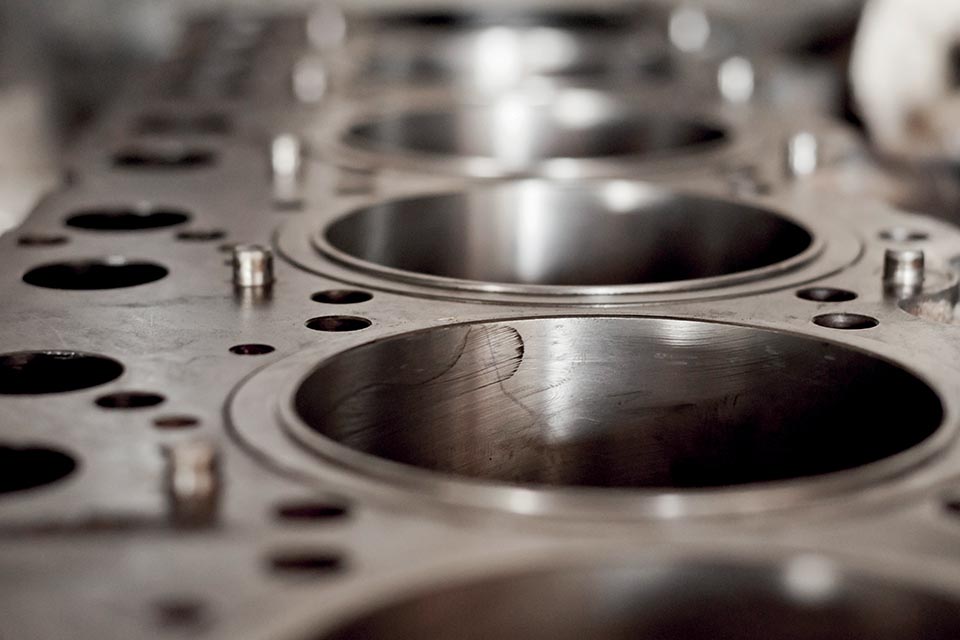

- Aluminium castings subject to dynamic loads

- Critical parts made from aluminium alloys

- Components where surface finish is important

- Cosmetic, ornamental and decorative castings

Aluminium densification

Bodycote offers Hot Isostatic Pressing, a casting densification service specifically for aluminium to remove porosity and increase the performance of aluminium alloys. Among these is Densal®, exclusively offered by Bodycote.

Designed, tested, proven

After several years of trials and verifications within the automotive industry, Bodycote’s team of technical experts developed the Densal® process. Since its launch, Densal® has been adopted and integrated into the production processes of major OEMs and their Tier 1 suppliers. It has successfully improved aluminium components and generated cost savings for the supply chain.

Using Densal® in combination with best practice foundry techniques result in a significant improvement in the mechanical properties of cast parts compared to parts without Densal® treatment, producing high quality, porosity-free cast aluminium components.