loading

The Power To Deliver - a component journey

Aircraft Turbine Blades And Vanes

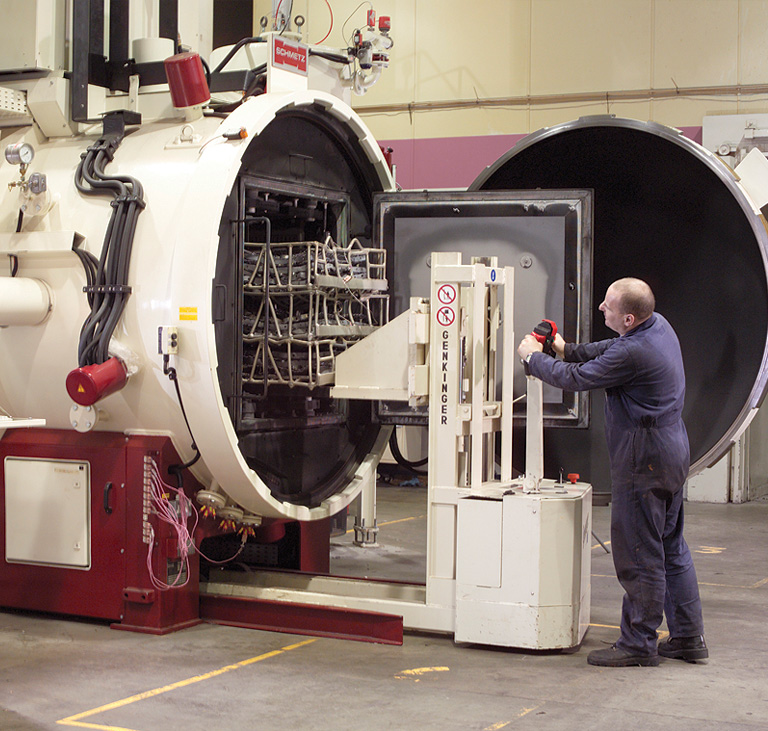

Aircraft turbine blades and vanes must withstand extreme temperatures in operation. These materials frequently operate at temperatures approaching their melting point – heat treatment, HIP and the use of surface technology allow these blades to operate reliably at these high temperatures for extended periods of time.

The turbine blades begin life as nickel-based superalloy ingots or billets. This superalloy gives superior strength at high working temperatures.

The billets are investment cast to form the blade shape and then fettled to remove casting material.

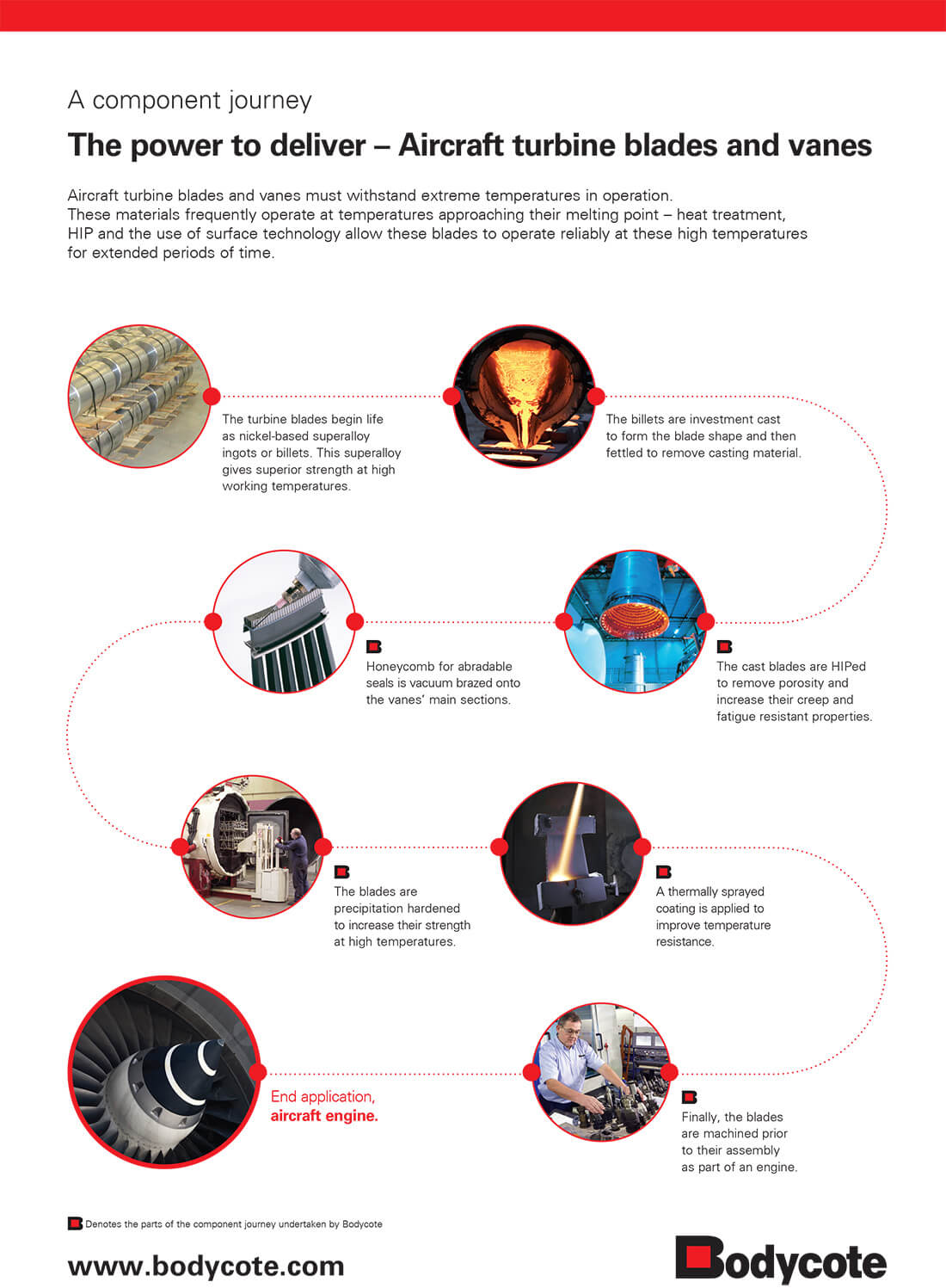

The cast blades are HIPed to remove porosity and increase their creep and fatigue resistant properties.

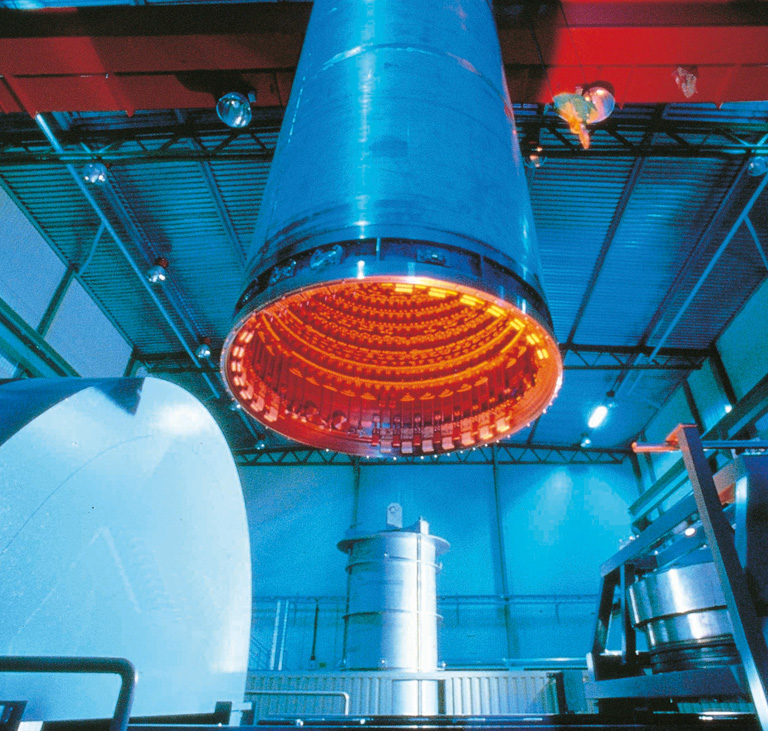

Honeycomb for abradable seals is vacuum brazed onto the vanes’ main sections.

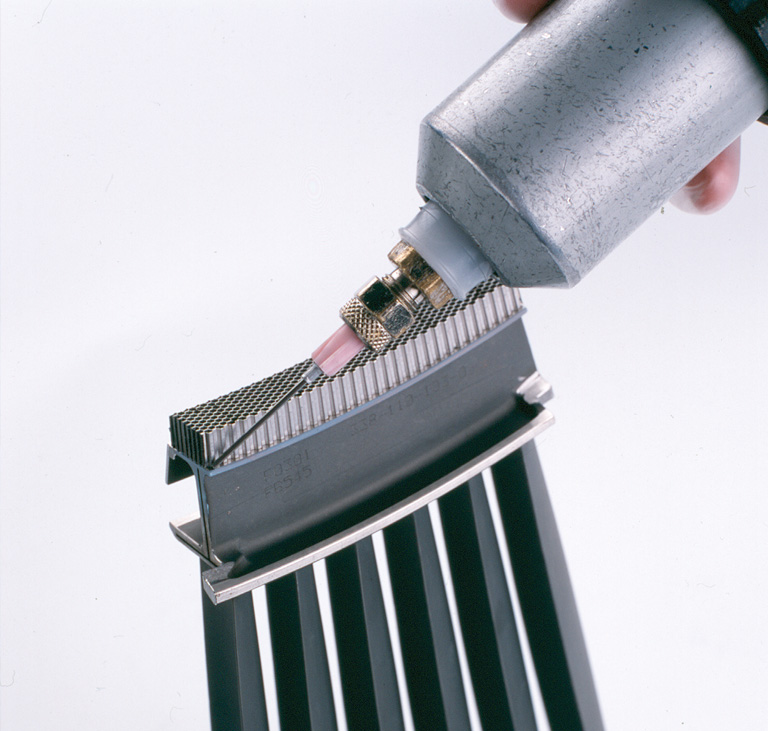

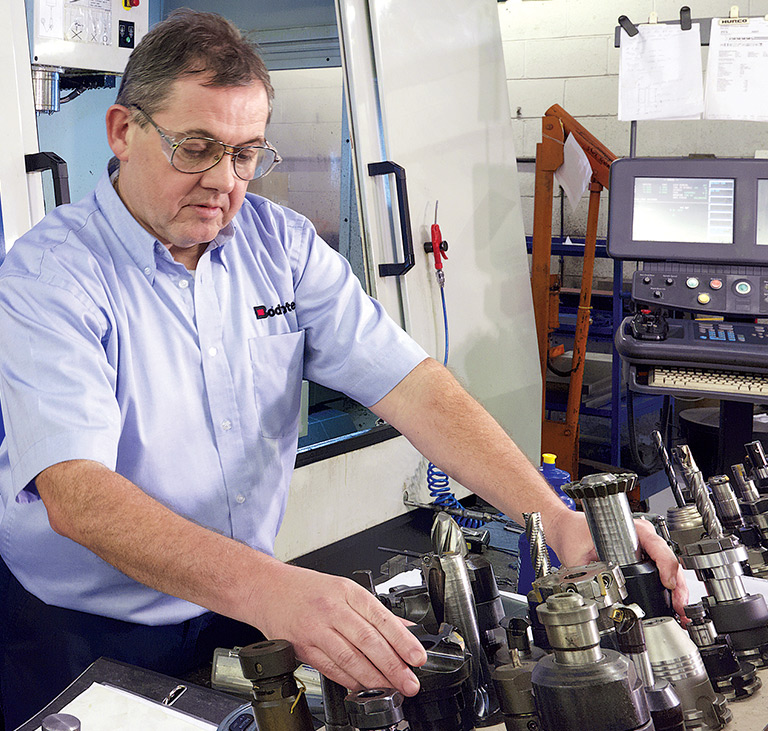

The part undergoes final machining and grinding.The blades are precipitation hardened to increase their strength at high temperatures.

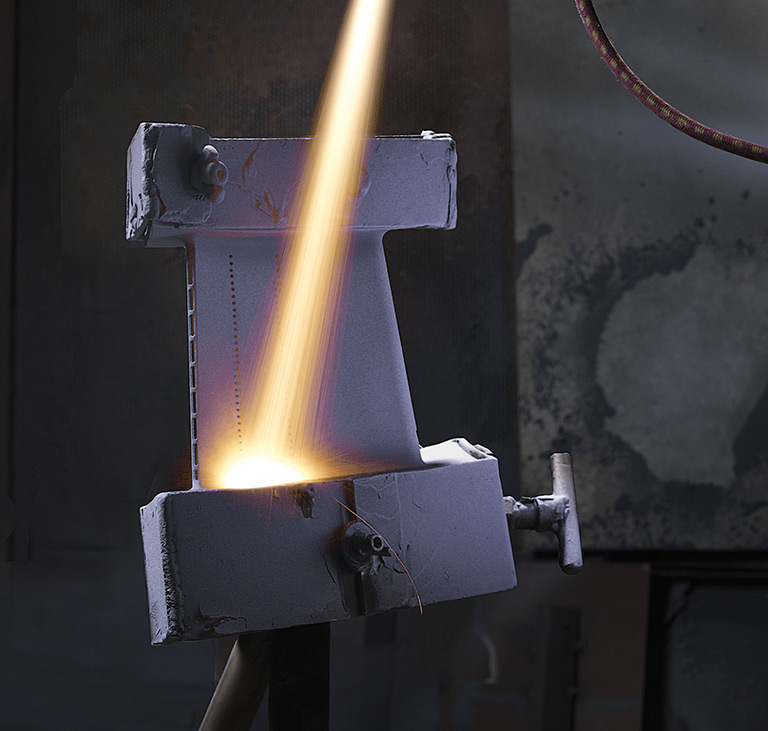

A thermally sprayed coating is applied to improve temperature resistance.

Finally, the blades are machined prior to their assembly as part of an engine.

End application – aircraft engine.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote

Denotes the parts of the component journey undertaken by Bodycote