loading

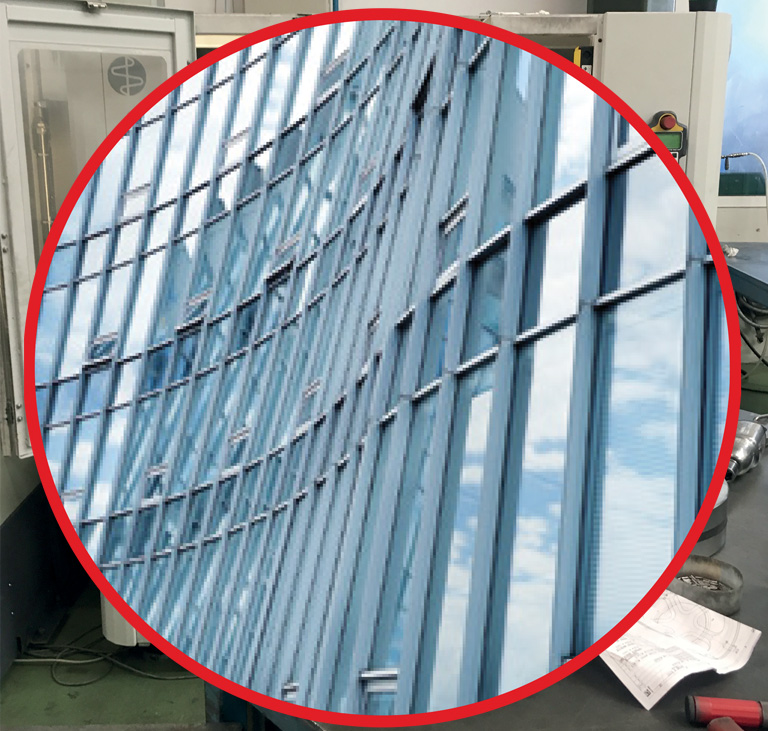

Strong profile - a component journey

Aluminium dies

Aluminium extrusion dies are used to manufacture aluminium profiles for a wide range of industries. During their working life they are subject to erosion and wear and this can cause defects in the aluminium parts they are used to produce. Bodycote’s nitriding processes improve the surface properties of these dies, providing optimal durability and wear resistance.

The metal die begins life as forged steel bar.

A section is cut from the bar and machined to the die shape required.

The part undergoes a stress-relieving heat treatment to eliminate material stresses introduced during the forging process.

The die is nitrided using a low pressure process. The introduction of Nitrogen into the surface gives increased hardness, toughness and ductility.

The part is inspected and its core hardness is tested against specification.

The die is finish machined using processes such as grinding, EDM and polishing.

End application - aluminium profiles are used for a wide variety of applications, such as window profiles.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote

Denotes the parts of the component journey undertaken by Bodycote