loading

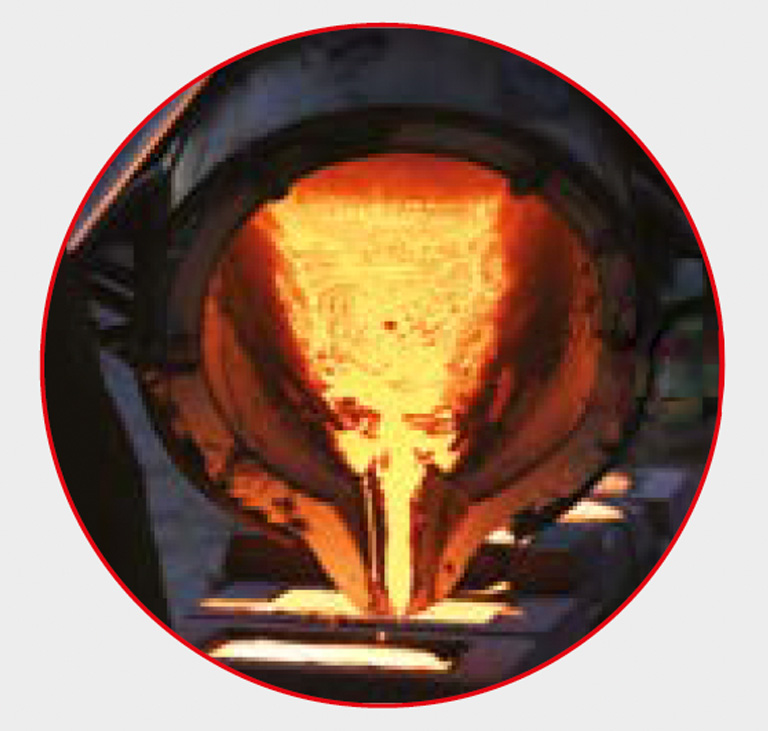

Steel bite - a component journey

Dental implants

Dental implants must be exceptionally strong, resistant to corrosion and able to withstand repeated pressure. They require heat treatment processing to ensure they have the properties needed, such as mechanical strength, and surface hardness and corrosion resistance. Specific medical approvals ensure treatments meet strict criteria for processing and cleanliness.

Dental implants begin life as martensitic stainless steel bars, selected for their corrosion resistant properties as well as mechanical strength.

The implants are machined to shape.

Implants are hardened under vacuum to avoid contamination, and to optimise fatigue resistance, with precise process parameters to limit distortion ensuring allowance for final grinding tolerances.

Implants are hardened under vacuum to avoid contamination, and to optimise fatigue resistance, with precise process parameters to limit distortion ensuring allowance for final grinding tolerances.

Implants are quality inspected to check for any contamination or evidence of pitting corrosion.

End application - food and beverage production.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote

Denotes the parts of the component journey undertaken by Bodycote