loading

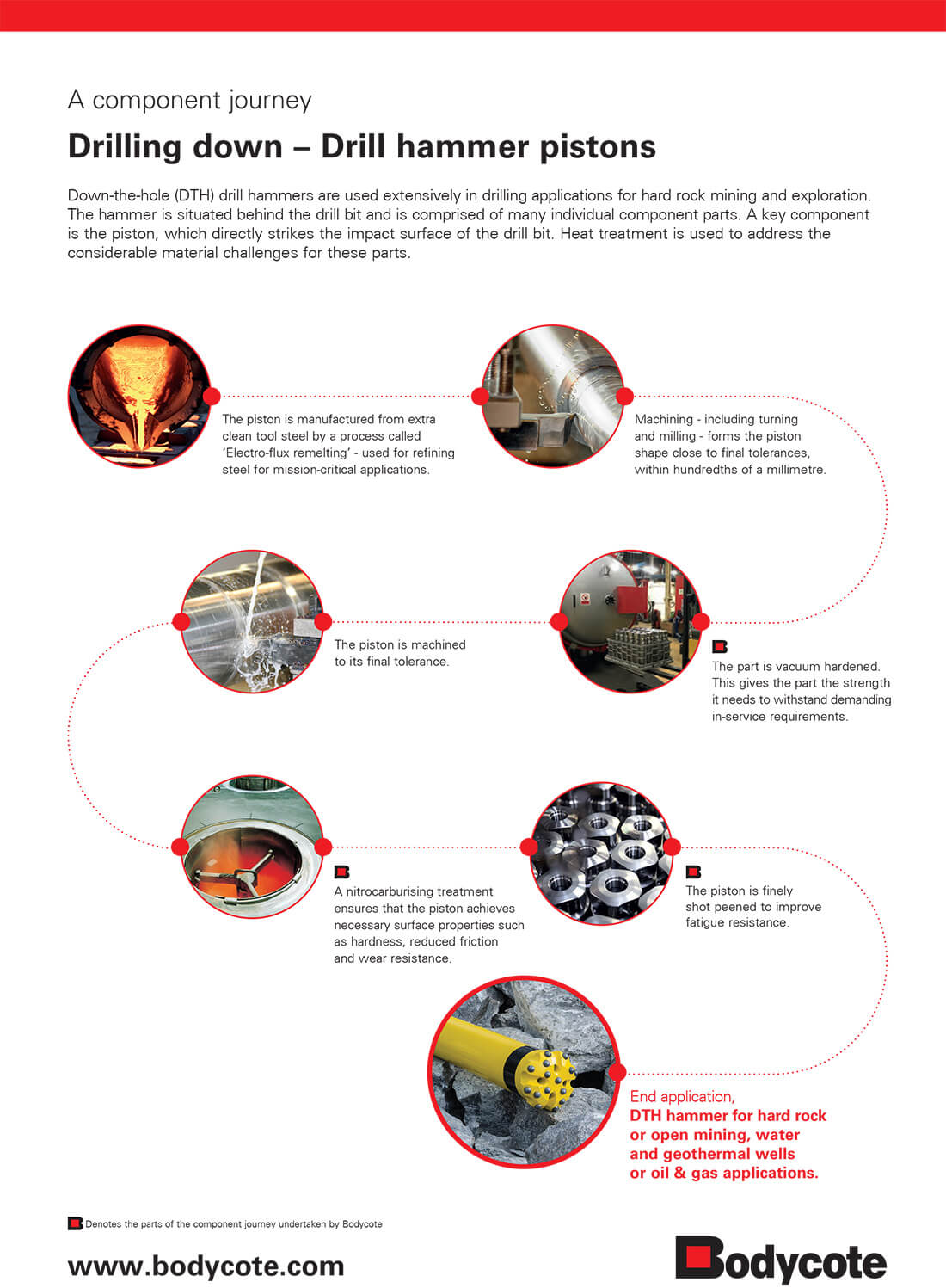

Drilling down - a component journey

Drill hammer pistons

Down-the-hole (DTH) drill hammers are used extensively in drilling applications for hard rock mining and exploration. The hammer is situated behind the drill bit and is comprised of many individual component parts. A key component is the piston, which directly strikes the impact surface of the drill bit. Heat treatment is used to address the considerable material challenges for these parts.

The piston is manufactured from extra clean tool steel by a process called ‘Electro-flux remelting’ - used for refining steel for mission-critical applications.

Machining - including turning and milling - forms the piston shape close to final tolerances, within hundredths of a millimetre.

The part is vacuum hardened. This gives the part the strength it needs to withstand demanding in-service requirements.

The piston is machined to its final tolerance.

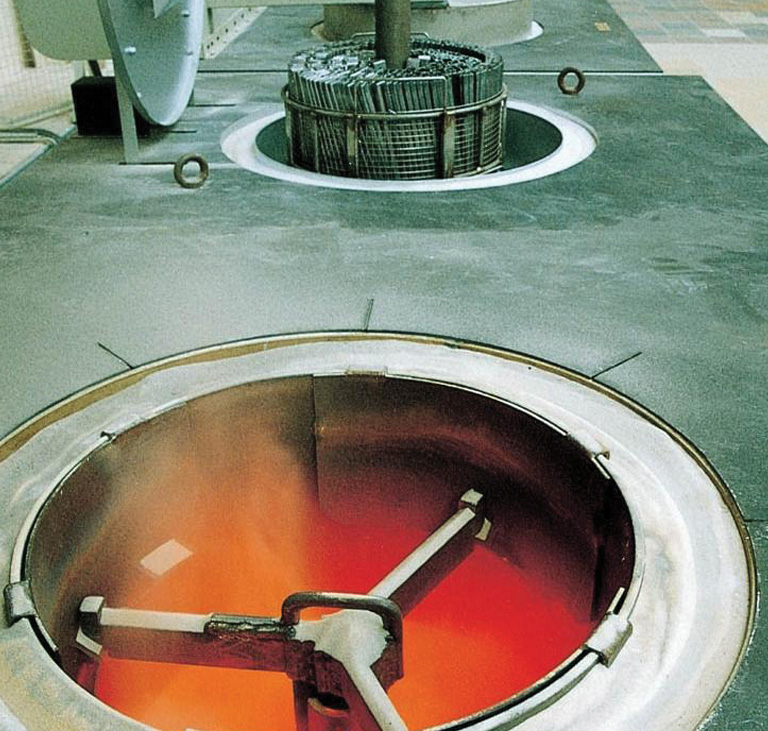

A nitrocarburising treatment ensures that the piston achieves necessary surface properties such as hardness, reduced friction and wear resistance.

The piston is finely shot peened to improve fatigue resistance.

End application - DTH hammer for hard rock or open mining, water and geothermal wells or oil & gas applications.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote

Denotes the parts of the component journey undertaken by Bodycote