loading

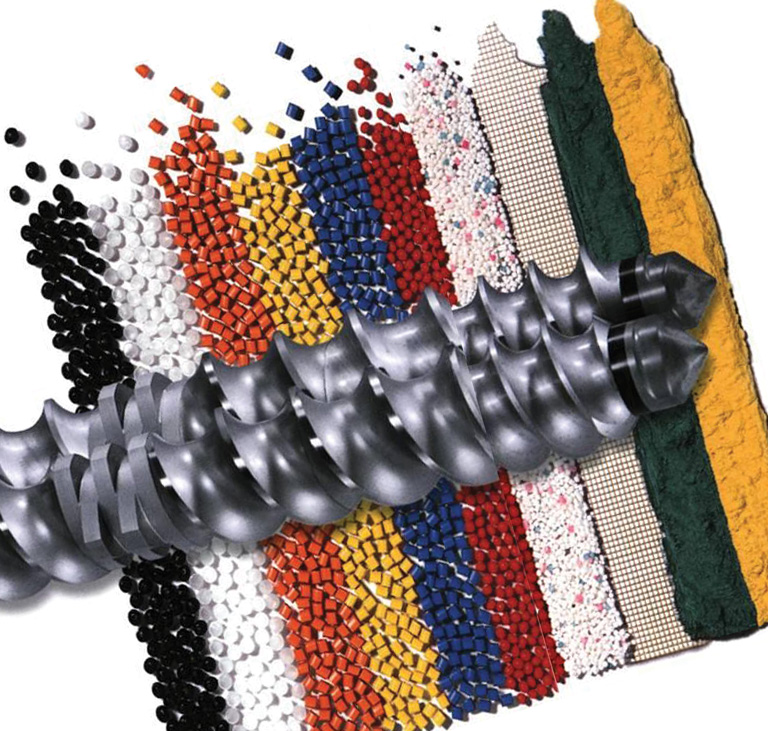

A Twist To Resist - a component journey

The extruder screw begins life as a forged steel bar.

An empty cylindrical steel capsule is manufactured. The steel bar is placed into the centre and the free volume is filled with metal powder.

The bar requires cladding to add a layer of wear-resistant material. This material will be produced from high quality steel powder.

The capsule is HIPed to fully densify the powder metal and bond the steel bar creating a coating.

The outer profile is machined to the final shape and dimensional tolerances.

The finished screw is hardened and tempered using a thermal cycle engineered to allow the material to retain toughness whilst allowing optimum hardness characteristics in the (clad) surface.

K-Tech coating applied for increased wear resistance, corrosion protection, and anti-galling.

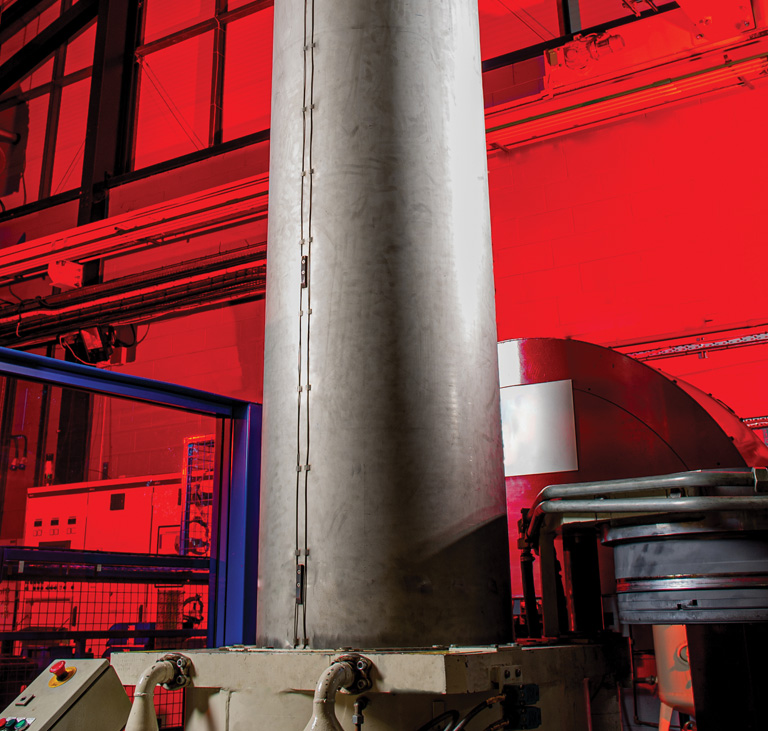

End Application

Plastic extrusion equipment.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote

Denotes the parts of the component journey undertaken by Bodycote